Williams Tools

EEN BEGRIP IN DE ZWARE INDUSTRIE.

Williams Tools deinst nergens voor terug: geen enkele klus of uitdaging, in welke sector dan ook, is voor ons te groot. Williams biedt al sinds 1882 de zwaarste uitdagingen van de meest veeleisende sectoren het hoofd.

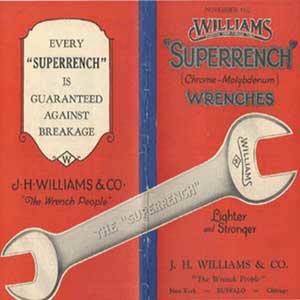

Williams was een van de eerste fabrikanten ter wereld dat met valhamers gesmeed gereedschap, een sleutel met een hoek van 15° en ringsleutels voor intensief gebruik in massaproductie nam. Een eeuw en een kwart later leveren wij nog steeds unieke en innovatieve producten voor die sectoren, waarbij aan steeds hogere eisen moet worden voldaan.

Williams Tools: onze geschiedenis, uw toekomst.

Williams - VERTROUWD. STERK. GEWAARDEERD.

Williams heeft een rijk verleden op het gebied van samenwerking met professionals uit de industrie.

(Video momenteel in het Engels)

DE TROTSE GESCHIEDENIS VAN WILLIAMS TOOLS

Williams maakt al sinds 1882 vol trots krachtig gereedschap waar professionals uit de industrie op vertrouwen.

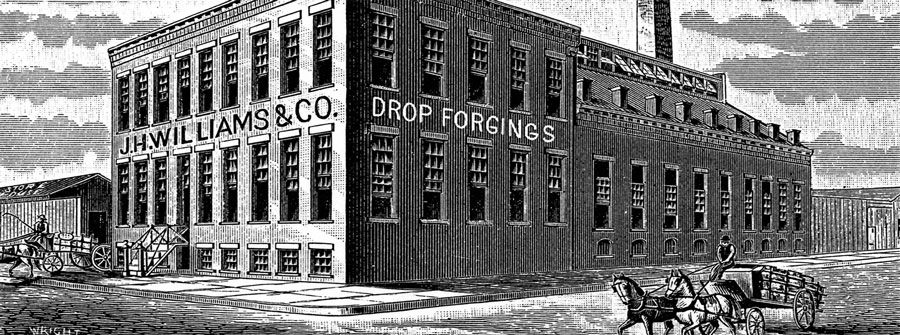

De eerste fabriek in Red Hook, Brooklyn, New York, zorgde voor een revolutie in de smederij. Hierbij werden machines ingezet om ervoor te zorgen dat alle onderdelen met dezelfde consistentie en kwaliteit werden gemaakt.

Dankzij dit nauwkeurige fabricageproces werden de producten van Williams gebruikt in de vele industriële werkplaatsen van het 19e-eeuwse Amerika. Van het maken van gereedschap voor fietsen, naaimachines en meer tot de productie van de koppen van golfclubs voor een groeiend Amerika.

1882

De eerste Williams fabriek in Red Hook, Brooklyn, New York, zorgde voor een revolutie in de smederij. Hierbij werden machines ingezet om ervoor te zorgen dat alle onderdelen met dezelfde consistentie en kwaliteit werden gemaakt.

Dankzij dit nauwkeurige fabricageproces werden de producten van Williams gebruikt in de vele industriële werkplaatsen van het 19e-eeuwse Amerika. Van het maken van gereedschap voor fietsen, naaimachines en meer tot de productie van de koppen van golfclubs voor een groeiend Amerika.

1893

Producten met een unieke kwaliteit, inrichting en verfijning betekenden alles voor het jonge merk Williams. De fabriek in Red Hook was brandschoon. Deze was voor die tijd vooruitstrevend: ze recycleerden olie en de fabriek zelf had een brandveilige constructie en beschikte over een eigen brandweerafdeling.

Met zijn aandacht voor detail en precisie oogstte Williams tijdens de wereldtentoonstelling van 1893 in Chicago speciale lof voor zijn kenmerkende, gepolijste uitstalling van esdoornhout.

Heden

Vandaag de dag heeft Williams fabrieken van wereldklasse verspreid over de Verenigde Staten. We blijven net zoals vroeger hoogwaardig gereedschap maken voor industriële toepassingen.

Wij blijven u van dienst, of u nu in het veld, op grote hoogte of in de fabriek werkt. Williams is uw vertrouwde, sterke en gewaardeerde partner.

SPEERPUNTEN

INDUSTRIËLE HYDRAULICA

KWALITEITSPRODUCTEN. UITGEBREIDE SELECTIE.

Williams levert een breed assortiment hydraulicaproducten, waaronder cilinders (trekcilinders, enkel- en dubbelwerkend, platte behuizing, aluminium, borgmoer, holle as, draadgat en laag profiel), pompen (handbediend, dubbelwerkend, lucht, gas, elektrisch (met magneetklep, met automatische terugslagklep, met peerschakelaar), diesel), 55T en 100T werkplaatspersen, teenkrikken, minikrikken, potkrikken, spreiders en 4T en 10T onderhoudssets.

Onze minikrikken kunnen tot maar liefst 20 ton tillen en ze passen letterlijk in de palm van uw hand – enorm veel kracht in een klein formaat. Williams hydraulische accessoires omvatten meters, adapters, koppelingen, slangen en hydraulische olie, evenals accessoires voor cilinders en werkplaatspersen.

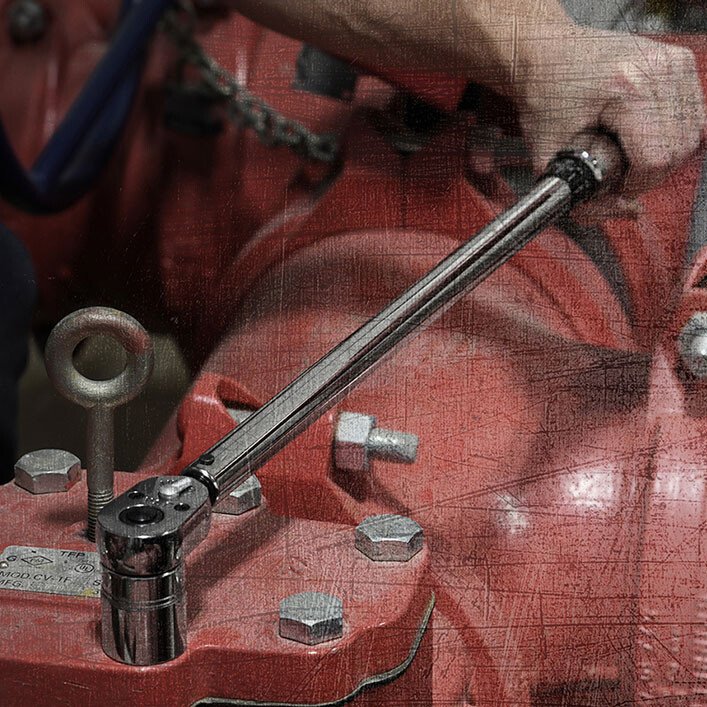

TORQUE-OPLOSSINGEN

HET JUISTE KOPPEL

In industriële toepassingen is het juiste koppel belangrijk voor de veiligheid, betrouwbaarheid en prestaties. Elke fabrikant, of deze nu oplossingen levert voor het onderhoud van wagenparken, de energiesector, de olie- en gasindustrie, enz. specificeert om belangrijke redenen een kritisch koppel voor bevestigingsmiddelen. Het te strak of te losjes aandraaien van kritische bevestigingsmiddelen kan leiden tot productstoringen. Productstoringen zorgen op hun beurt weer voor onnodige uitvaltijd, hogere kosten, mogelijk letsel en meer.

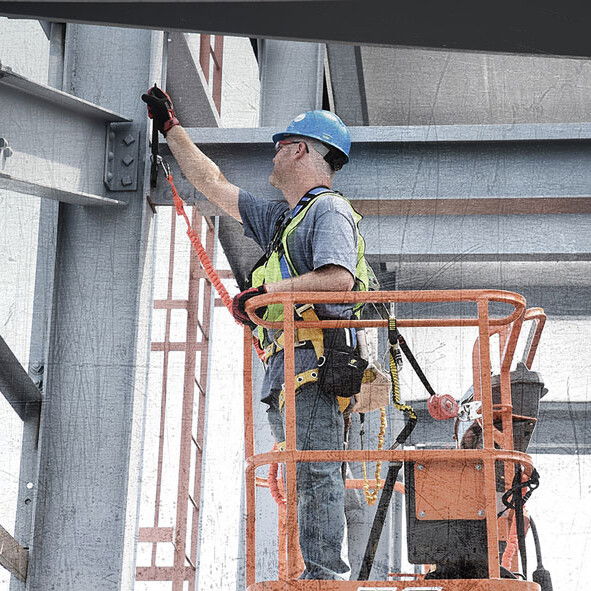

TOOLS@HEIGHT

- BESPAAR TIJD EN GELD – De nauwkeurig ontworpen bevestigingspunten hinderen de functionaliteit van het gereedschap niet.

- VERSLA DE STATISTIEKEN – Het Tools@Height-systeem koppelt elk stuk gereedschap aan zijn eigen koord, beperkt het aantal verwisselde stukken gereedschap tot een minimum en verkleint de kans op naar beneden vallend gereedschap.

- RISICOBEPERKING – Dankzij de onafhankelijke gereedschapslijn kan het gereedschap met één hand uit de holster worden gehaald en er weer in terug worden geplaatst, zodat de gebruiker zich aan de kritische “drie contactpunten”-regel kan houden bij het werken op hoogte.

- BEHOUD DE CONTROLE – Dankzij onze modulaire aanpak kunt u gereedschap en holsters aanpassen aan uw behoeften.

- LAAT HET OVER AAN DE EXPERTS – Wij stellen samen met u uw valpreventiebehoeften vast en bieden u vervolgens een compleet systeem waarmee uw team veilig en efficiënt kan werken.

WilliamsWork Tools

De hoogst gewaardeerde productiviteitsoplossingen in de industrie.

Deze catalogus bevat een productreeks die is toegespitst op grote afmetingen en een robuuste kwaliteit. Dit gereedschap houdt stand wanneer ander gereedschap het allang heeft opgegeven onder de zware omstandigheden van de hedendaagse energie- en petrochemische industrie.

ONZE PROGRAMMA ‘S

Bij Snap-on koesteren we een lange traditie van vakmanschap, kwaliteit en innovatie. Onze producten zijn licht, duurzaam, sterk en bovenal veilig.

FOREIGN OBJECT DAMAGE BEHOORT VANAF NU TOT HET VERLEDEN

NIEUWS EN

UPDATES

Blijf op de hoogte van het laatste nieuws over onze producten en aankomende evenementen.

Snap-on Industrieel bij AERO Friedrichshafen 2024

The world‘s leading trade show for general aviation celebrates its 30th anniversary this year. Discover what direction developments in the General Aviation industry are going at the AERO…

Gereedschapsbeheer tilt de voedselveiligheid binnen KP Snacks naar een nog hoger niveau

KP Snacks heeft aangekondigd dat het Snap-on ‘s gereedschapsbeheer in zijn productielijn heeft geïmplementeerd...

Wij helpen een Fokker F27 te restaureren

Bij Snap-on Industrial zijn we er trots op dat we een ambitieus project in Nederland ondersteunen om een vintage Fokker F27 te restaureren en weer de lucht in te krijgen.

Het nieuw verbeterde gereedschapsbeheersysteem van Snap-On – gegelanceerd op het prestigieuze Red Bull Racing-hoofdkantoor in Milton Keynes

Met genodigden uit onder meer de energieopwekkings-, lucht- en ruimtevaart- en spoorwegindustrie biedt het verbeterde productassortiment van Snap-on nu een volledig verbonden ervaring, aangedreven door de modernste software om teams te helpen sneller en slimmer dan ooit tevoren te werken.

Snap-On.WIJ ZETTEN ONS IN VOOR DE VEILIGHEID VAN UW PERSONEEL EN KLANTEN.

Bij Snap-on koesteren we een lange traditie van vakmanschap, kwaliteit en innovatie. Onze producten zijn licht, duurzaam, sterk en bovenal veilig.

Snap-On.WIJ ZETTEN ONS IN VOOR DE VEILIGHEID VAN UW PERSONEEL EN KLANTEN.

Bij Snap-on koesteren we een lange traditie van vakmanschap, kwaliteit en innovatie. Onze producten zijn licht, duurzaam, sterk en bovenal veilig.

KUNNEN WE U HELPEN?

Vul hieronder uw gegevens in. Vervolgens neemt iemand van ons team contact met u op.

"*" indicates required fields

KUNNEN WE U HELPEN?

Vul hieronder uw gegevens in. Vervolgens neemt iemand van ons team contact met u op.

"*" indicates required fields